Abstract: After the release of the power reform document, private capital entered the power market. Many enterprises participate in the distribution, operation and maintenance market. How to improve the operation and maintenance means of these operation and maintenance service providers, reduce the cost of operation and maintenance, and enrich the means of competition has become the focus. From the perspective of intelligent operation and maintenance, this topic describes the help and improvement of information and intelligence to operation and maintenance service providers.

Energy interconnection cloud platform based on big data

Throughout history, the development and transformation of energy have gone through the following three stages:

The first industrial Revolution: the main energy was developed from wood to coal, and the coal-fired steam engine became the main power of production. Since then, mankind has entered the era of fossil energy dominated by coal.

The second Industrial Revolution: from the age of steam to the age of electricity, oil replaced coal as the main energy source.

Energy Internet era: multi-layered interaction, intelligent supply and use of energy make it possible to combine multiple energy sources.

Comprehensive energy services

On the basis of existing traditional energy services, such as thermal power plant, gas and power grid, combined with new technologies such as solar energy, garbage biogas power generation and triple power supply, big data and cloud computing are utilized to make energy interconnection, energy management, energy electricity sales and market distribution available to users.

Energy Internet cloud platform

In the overall integrated energy service, all data generated will be interacted through the real-time interconnection of the Internet. How to use this data to serve customers and reduce the operating costs of energy Internet companies has become a key issue.

At present, the incremental distribution network, energy management and business operation of the park inevitably face a problem, that is, how to realize intelligent operation and maintenance?

Current situation of intelligent distribution operation and maintenance

At present, the energy provided to users is mainly divided into two types: one is electric energy, and the other is other new energy, such as heat co-supply, gas supply, heating and cooling, which all need maintenance. In many cases, electricity, as the medium of intermediate exchange, is the most important means of energy transmission, so the content here is mainly from the perspective of intelligent distribution operation and maintenance.

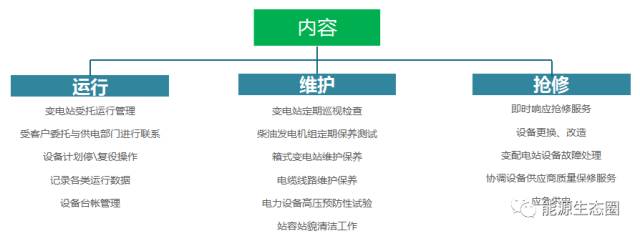

In my opinion, intelligent operation and maintenance should include at least the following three aspects:

Operation: Substation operation management is the most basic aspect; The second is the planned shutdown/resumption of service of the equipment. The service provider should be fully responsible for everything after the user takes care of the distribution room. At the same time, it is necessary to record all kinds of operation data, including whether the power distribution room is in good condition; Finally, the management of equipment ledger, such as how many places of operation and maintenance, needs to be managed.

Maintenance: Maintenance requires regular inspection, regular maintenance of all equipment in the distribution room, substation, and line cable, high-voltage preventive test of power equipment, and cleaning of station appearance.

Rush repair: in case of customer failure, timely respond to rush repair, emergency power supply, replacement and renovation of equipment, coordinate equipment suppliers to provide quality assurance services, etc.

Currently, operator, this piece is by artificial patrol, most of the time are three ways to implement the paper records and telephone communication, especially designed user side, the original distribution are old, no means of intelligence, mainly manual patrol, patrol after paper records, communicate with the user through the phone.

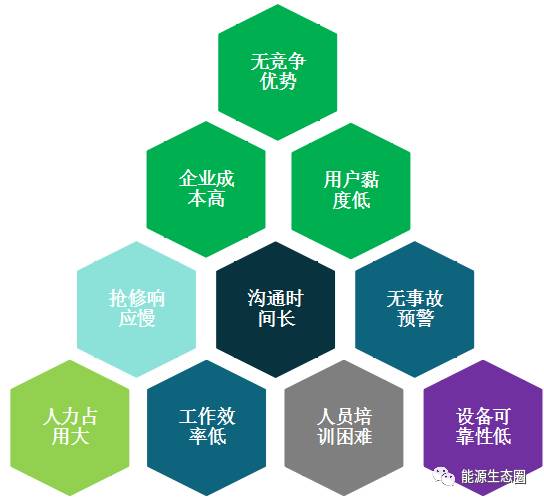

Traditional operation and maintenance is actually a kind of labor-intensive business, and there are still many disadvantages:

1. The occupation cost of manpower is very high, and most of the work needs to be done by manpower;

2, low work efficiency, under normal circumstances, maintenance patrol is two people a car, in the scope of the designated maintenance, in addition to the time spent on the road and communication time, so the work efficiency is low;

3. Personnel training. With the expansion of business and the addition of more and more users, personnel training is needed. The current training mode is basically teaching and mentoring. Due to the low possibility of accidents, the personnel have little fault simulation, and the equipment does not have real-time online monitoring, we can only learn from the emergency repair after the accident.

4. Communication takes a long time. Non-urgent events are usually communicated with users over the phone.

5, rush repair response time is relatively long, rush repair is generally initiated by the user, rarely found by the operation and maintenance companies. Due to the deviation of the user's description of the fault, the user's description may be inconsistent with the problem found on site, which seriously affects the timely response to rush repair.

These problems lead to high operating costs and low user stickiness, which reduce the competitive advantages of operation and maintenance companies.

Distribution intelligent operation and maintenance requirements

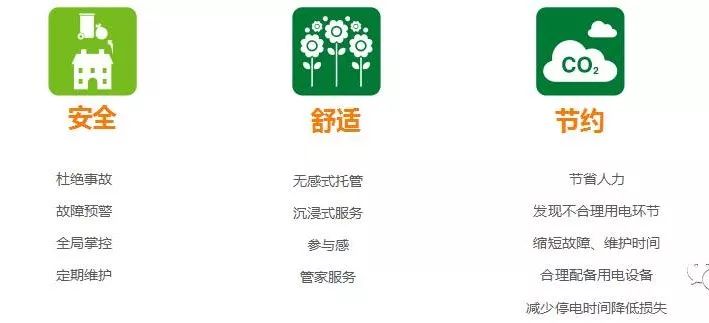

From the perspective of users and energy providers, intelligent operation and maintenance needs have the following three aspects:

Safety: The best situation is to put an end to accidents, then how to do to put an end to accidents?

1, do a good job of fault early warning, before the accident does not happen to kill the hidden trouble in the cradle;

2. Master all states;

3. Regular inspection is necessary, but a weekly inspection cannot solve all problems.

Comfort: It can be summarized in a few key words.

1. Non-inductive hosting: after the user hosts the distribution room, the service provider shall be fully responsible for the occurrence and solution of problems without the user's concern;

2. Immersive service: it is necessary to make users not only feel you, but also feel you are everywhere. Service providers will know the problem more quickly than users and come up with solutions.

3. Sense of participation: The user knows everything about the operation and maintenance of the distribution room, including how much power is used and the safety and security of the distribution room. All the users are very clear about the situation;

4. Butler service: Provide services to users with the service attitude of a butler.

Save:

For users:

1. The user entrusts the power distribution room, saving manpower;

2. The loss will decrease with the decrease of accidents;

3. It is also a kind of saving to find some unreasonable power consumption links to carry out energy saving transformation in time.

For energy providers:

1. With fewer personnel, it used to be necessary to conduct inspection once a week, but once two weeks may be enough after the new technology is adopted;

2. In terms of the allocation of the whole process, it will provide a better control means for the operation and maintenance companies and reasonably allocate resources so as to reduce costs.

The core of distribution intelligent agent operation and maintenance service is:

The application of computer network technology and modern communication technology to the distribution room maintenance service is also an initiative and a model to improve the reliability and efficiency of the maintenance service. Improve the reliability and efficiency of power distribution room maintenance by means of science and technology

A professional operations company

Do professional business for users

Provide professional services

Professional team, this team is the operation and maintenance operators have, users do not have

Professional tools, there are a lot of professional equipment to provide services for users, to achieve user needs

Relying on the innovative thinking concept of Internet + and through online information technology collection and intelligent data analysis, the company provides customers with systematic, professional and standardized offline services to achieve effective interaction, change the traditional service scene, so as to achieve resource maximization, further expand the service boundary and create a new service mode.

Users can log in and manage the power distribution room through the web terminal of electricity service cloud platform, IOS& android mobile phone terminal and WeChat public account.

Intelligent operation and maintenance product planning:

1. The most basic of intelligent operation and maintenance products is to realize remote real-time monitoring and accurately know the operation status of the distribution room;

2. Use the analysis of historical data to change timely maintenance into on-demand maintenance. Some equipment is relatively old, so the frequency of maintenance should be increased appropriately, while the frequency of maintenance of new equipment can be reduced appropriately;

3, the substation operation mode analysis, in the power supply bureau to pay the electricity, one part of the capacity cost is negotiable, self-coordination;

4. Through the data parameters collected, a simple trend analysis is made on whether an accident has occurred, and the data is integrated;

5. Senior expert diagnosis service. The operator should know the fault occurred on site before the user, and have a preliminary prediction of the fault.

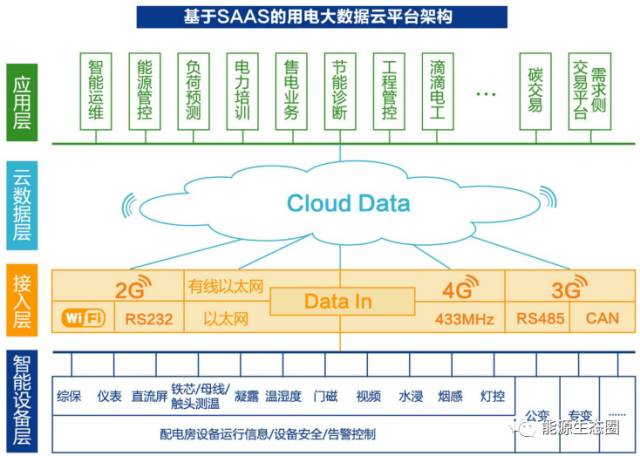

The SAAS based electricity big data cloud platform architecture can be divided into the following four levels:

智能设备层:这些设备层是装在配电房内的,大部分都是传感器,主要采集设备运行状态、环境状态等数据。

接入层:采集的数据通过接入层传到云平台,接入层主流的运行方式包括2G、3G、4G、LoRa、NB-LOT等。

云数据层:把所有数据集中在一个平台里,在这个平台上应用层就可以做很多应用,为能源运营商的业务拓展提供了可能。

应用层:可以做智能运维、能源管控、负荷预测、电力培训、售电业务、节能诊断等服务。

配电智能运维Intelligent equipment layer: These equipment layers are installed in the power distribution room. Most of them are sensors, which mainly collect the data of equipment operation status and environment status.

Access layer: The collected data is transmitted to the cloud platform through the access layer. The mainstream operation modes of access layer include 2G, 3G, 4G, LoRa, NB-LOT, etc.

Cloud data layer: All the data is concentrated in one platform. On this platform, the application layer can do many applications, providing the possibility for the business expansion of energy operators.

Application layer: It can provide services such as intelligent operation and maintenance, energy management and control, load forecasting, electric power training, electricity sales business, energy saving diagnosis, etc.

The topology of distribution intelligent operation and maintenance is targeted at energy operation providers and is roughly divided into four regions:

Operation and maintenance of distribution rooms

External application

Public network transmission